Software for managing the tightening of bolted joints made with electronic, electric, battery screwdrivers and torque wrenches, from any manufacturer, from automated data collection, operator guidance in the execution of the tightening in the programmed sequence, traceability and statistical control.

Through services and APIs, using different communication protocols, the software identifies the equipment and collects data in real time as the tightening is performed.

Compatible with any tool on the market like Atlas Copco, Stanley, Bosch, Desoutter, Acradyne, Ingersoll, Gleco, among others.

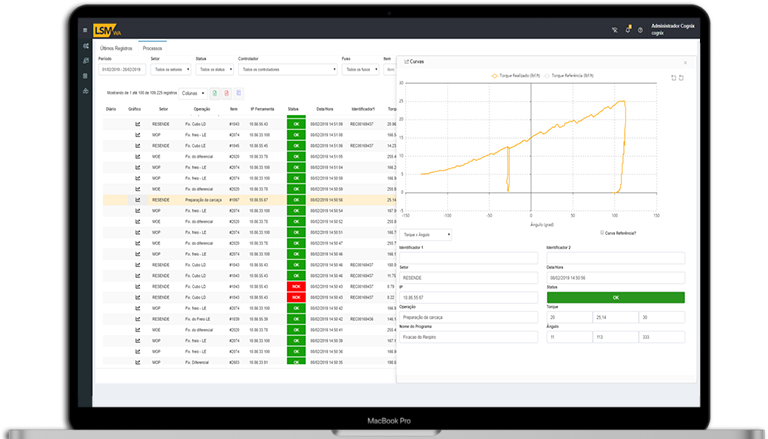

Information on all screw tightening performed in the product assembly process from any web browser.

Complete resume with product code data, operator name, screw code, date and time, torque, angle, status, torque x angle curves, torque x time, angle x time and tool alert events.

The system provides information that can easily minimize the extent of any recall.

Dashboards with online information and reports with process and product data, list of the latest tightening, top 10 NOK, standard curve analysis.

Detailed extract of the fastenings performed in the assembly operations, informing the lack of screws or NOK tightening.

Logbook to record the reasons for the occurrence of NOK tightening.

Record of tools with calibration information as certificate, supplier, date, time, person responsible and expiration.

Alerts are generated in advance informing the need for a new calibration avoiding the interruption of tool use.

Notification on the software interfaces and sending emails with events generated by the tools, calibration expiration alerts, daily summary of NOK torques, signaling of missing screws or NOK tightness in the final product check.

Meritor is a global supplier of axle, brake and suspension solutions for equipment manufacturers in the transportation and industrial sectors.

In Brazil, the company implemented the Torque Digital solution in order to have real-time information on the shop floor and traceability of all torques of its products. Digital Torque solution in order to have real-time information on the shop floor and traceability of all torques of its products.

We automate the collection of torque, curves and alerts data from more than 80 electronic screwdrivers, from different manufacturers, installed in the Meritor's assembly lines in Osasco (SP) and Resende (RJ).

Known for its strict quality control, Embraer has chosen our digital torque solution for control and traceability in the execution of screw tightening, within the limits established in the sequence and programmed stages, of the KC390 tactical and logistical transport aircraft.

Industrial tablets with an operator's guidance are used to perform the tightening with screw sequence control, selection of the tightening programs on the tools based on routes previously set by engineering and drag torque compensation control.

All data are stored in a database for consulting and exporting product reports.

Fill out the form with your data, and we will contact you to schedule a demonstration.

Discover how we can transform your plant into an innovative and technological environment