LSM MES is a modular system that digitizes information on the shop floor, executes and monitors manufacturing operations, applies controls to ensure on-time delivery and product quality, optimizes material handling and promotes integration between all company areas.

Connection with ERP, APS, PLM, EDI communication between automotive chain suppliers.

Data acquisition of equipment with several drivers and industrial protocols.

Planning, execution and monitoring of production orders, WIP and material consumption, guarantee in the execution of flows, routes and operations.

Information on raw materials and finished products at different stages of the process.

Traceability of process data collected in the execution of production orders.

In assembly, quality inspection and material delivery.

Operator's guidance in the processes for the execution of the operations without errors.

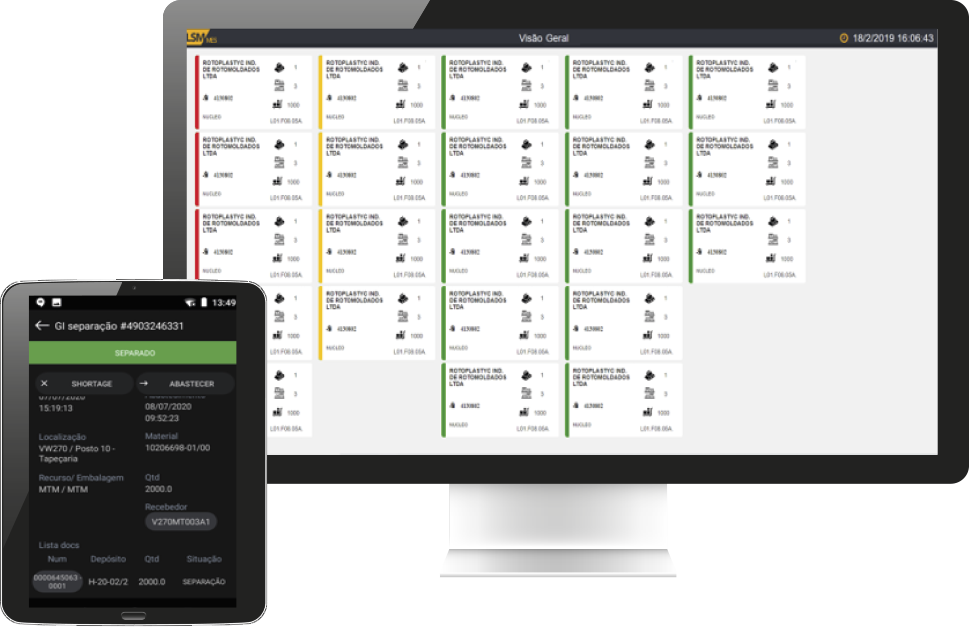

Reliable online information available on any device, anywhere. Dynamic dashboards with indicators, alerts and help chain.

Document organization, version control avoiding out-of-date information on the shop floor, fast search for metadata.

User management integrated with ERP. Skill matrix and job rotation. Facial detection for user login.

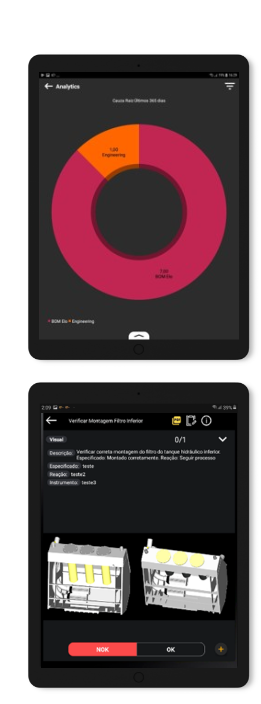

Through reports, dashboards and dynamic queries, configurable by system users, it is possible to understand and improve the manufacturing process quickly.

Rapid deployment taking advantage of resources and infrastructure installed on customer premises. With drag & drop features, create and modify workflows and production orders, no software developer skills are required.

Tool that automates quality management in production, guarantees the execution of control plans and monitors results in real time, notifies non-conformities for quick action, manages the execution of rework and ensures the delivery of products without errors.

Recording of defects and scrap through the system interfaces, preventing nOK products from advancing in the production process, generating indicators in real time.

Replace the traditional paper checklist with automated inspections using Artificial Intelligence and track the results on the LSM MES web interfaces.

Logbook for recording nonconformities and starting an action plan with identification of the root cause and actions taken.

Statistical process control with automated sample collection and generation of x-bar analyzes, cp/cpk, histograms.

Elimination of paper and manual notes, reduction in inventory costs and operational gain in logistics processes with the automation of tasks, integration with production and connection with ERP and MRP software.

Monitoring of material consumption of production orders and automated downtime ensuring accuracy of inventory and reliable information in real time.

Traceability of raw material lots to finished product.

Automation of the output and transfer of materials from the warehouse for separation, kitting and supply in production, prioritizing tasks, avoiding unnecessary movements and production losses due to lack of materials.

Control of product delivery through electronic checklists and shipment conference on mobile devices, ensuring delivery sequence.

E-kanban for signaling the demand for materials at different stock levels.

Prevention of production stoppages and quick action to correct failures.

Web and mobile interfaces for management and execution of preventive, predictive, corrective and improvement maintenance service orders.

Asset management, material stock, geolocation,calibration and information from QR code reading.

Generation of MTBF and MTTR indicators..

Predictive analysis with cognitive services predicting potential breakdowns.

TPM (Total Productive Maintenance) electronic checklists generating service requests from the notes of operators and maintenance personnel.

Quick access to request services through the software's web interfaces.

OS and Gantt chart for preventive maintenance plans.

Record of occurrence, action, photo/video evidence at the closure of the OS.

Management of equipment calibration, alerts and blocking of productive resources in case of expiration.

ISRINGHAUSEN is a world leader in the development and manufacture of commercial vehicle seats with products for the truck, bus, van, pick-up, train, boat and construction machinery markets.

South America's ISRI plants rely on LSM MES for automating the receipt of production orders from their customers, executing production orders in the contracted sequence(JIS), optimizing maintenance and logistics processes, eliminating paper and online information.

CNH Industrial operates in the manufacture of agricultural and construction equipment and machinery, trucks, commercial vehicles, buses and special vehicles.

The plants in Curitiba, Sorocaba and Piracicaba, seeking 4.0 industry technologies, implemented LSM Cognix for for automation, information digitalization, order sequencing, error proofing systems, torque digital, traceability and quality control with inspection by tablet.

Fill out the form with your data, and we will contact you to schedule a demonstration.

Discover how we can transform your plant into an innovative and technological environment